Faurecia

Faurecia Motim and other elements of Sketch Collaborative were tasked by Faurecia to fundamentally redesign the automotive seat cushion. The goal was to reduce the foam composition in the seat without hurting comfort and provide better lateral support while reducing pelvic drift. After several months of a wide and varied exploration, the design focused on a compliant surface with an underlying suspension system. The end result was a entirely novel cushion design with a strict slating structure and non-linear springs. […]

U-Labs

Motim Industries, working with U-Labs, designed and prototyped a water-saving dual flush system. This system allowed for the simple integration of a half or full flush option to existing toilets.

Dexela

Dexela developed a novel algorithm for constructing three dimensional data with relatively few x-ray images, reducing the dose thus opening the possibility of using this for screening procedures such as mammograms. Motim helped Dexela quickly create a prototype machine using a proprietary detector and a commercial X-ray source capable of moving incredibly fast. Motim also designed and fabricated a patient guard and breast clamp that accommodated the new motion.

Photoral

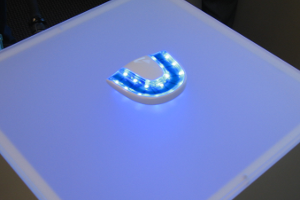

In the span of 3 weeks from start to finish, Motim created a functional prototype for an intraoral light based bacterial management system. The prototype had a custom PCB and firmware, a rechargeable battery, 32 LEDs and a mechanical enclosure.

Unilever

The skin care experts at Unilever worked with Motim on three projects to create prototype skin and scalp sensors to show the efficacy of their products. Using digital imaging, moisture sensing, magnification and polarized illumination, Motim created four separate designs. All of the models integrated industrial design and functioning electronics.

Medtronic

Medtronic Navigation Motim Industries has worked on many facets of the O-Arm three dimensional imaging system, both before and after Breakaway Imaging was acquired by Medtronic. In addition to designing many functional subassemblies and fixtures, Motim transitioned the cosmetic skins from low volume processes (such as vacuum forming and carbon fiber lay-up) to higher volume capable processes such as injection molding. These efforts led to a significant cost reduction and decreased manufacturing time.

Stonewedge | Lifespire

Stonewedge | Lifespire Working together with the electrical engineers at Lifespire, Motim guided the development of a senior-friendly communication platform. The system consisted of proprietary software and a USB peripheral device known as the Swan. The Swan incorporates a video camera for visual communication and accepts expansion cartridges to add functionality such as motion sensing or patient monitoring. The project started with a blank page and progress to tooled parts and preproduction prototypes. Motim ushered the product from conception to […]